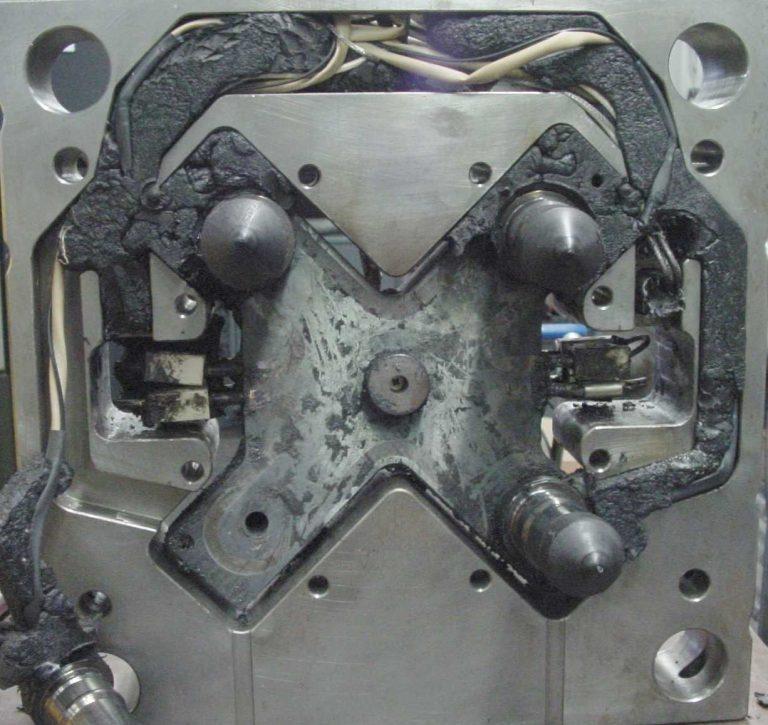

A decisive factor for production is the avoidance of melt damage to the hot runner and the associated hot runner leakages. This is because mould damage and the repair of a hot runner immediately have a negative impact on costs and time.

The majority of injection moulders know this problem only too well, because it is not uncommon for moulds with hot runner technology to leak. The moulding compound flows through a defect in the hot runner system into the backward mould technology.

With hot runner monitoring, you check whether the melt, due to leakages, runs over the manifold, nozzles and electronic connections as well as sensors. The leakages are detected at an early stage.

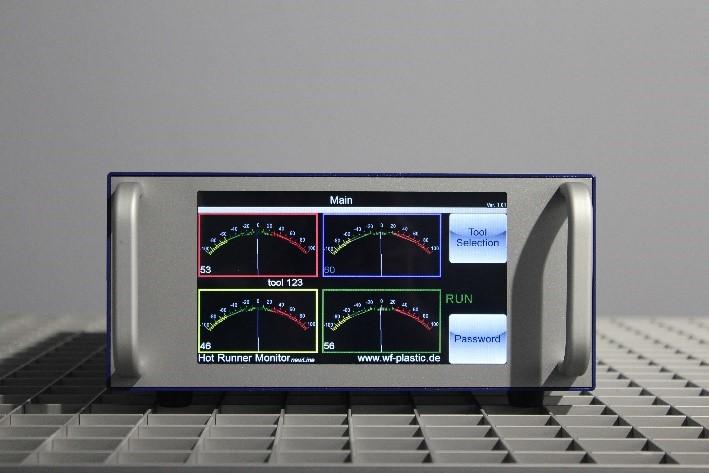

The patented Hot Runner Monitor from wf plastic was first established on the market for hot runner monitoring 20 years ago and has since established itself as a cost brake.

Causes of failures can be eliminated by early detection. Possible causes of leakage are:

In areas of possible leakage points, the stainless steel pipes are placed, through which a very low air flow is directed. To establish operational readiness, an air supply of 3...14bar is applied to the Hot Runner Monitor. The machine control is addressed via a potential-free contact in order to interrupt the injection molding process in case of detection.

Mehr Sicherheit

Gesteigerte Produktivität

Reduzierte Ausfallzeiten

Geringere Schadenskosten

Hot runner monitoring with up to 8 monitoring points

Hot runner monitoring with up to 16 monitoring points

Hot runner monitoring with up to 32 monitoring points