................ ., ., . . .. ..

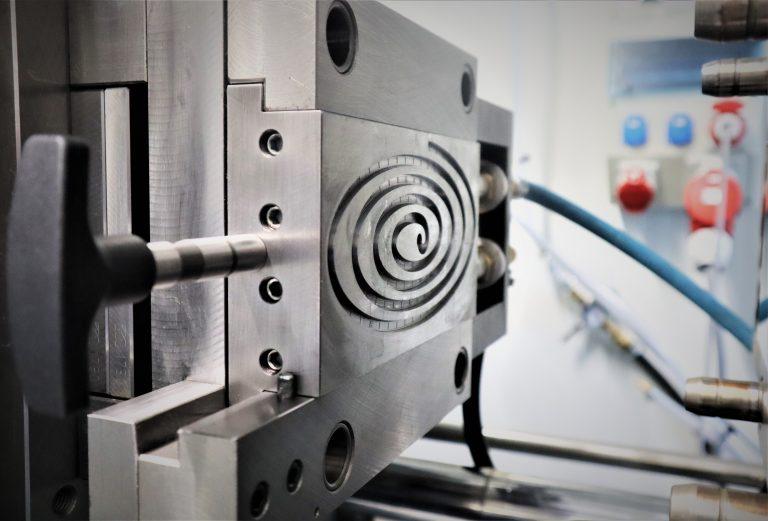

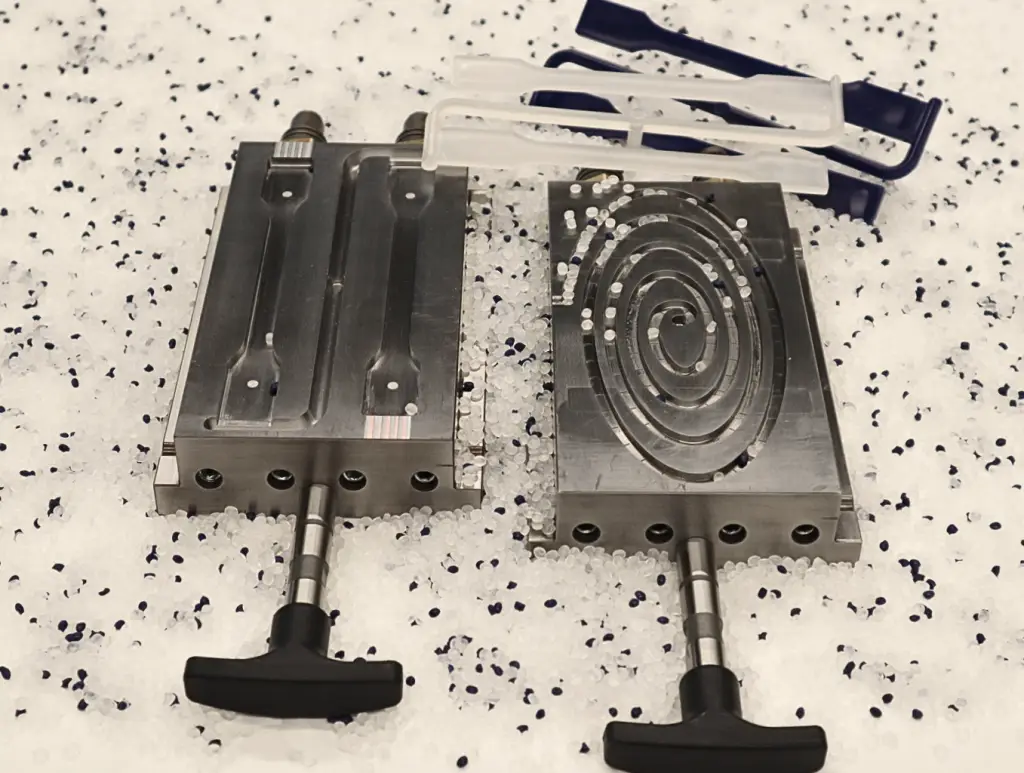

The test specimen mould of wf plastic consists of three parts to keep the cavity change for different material tests of the plastic as simple as possible. Thanks to the quick coupling system and a weight of 6kg per insert, the inserts can be changed at any time and at quick notice.

The master tool is for the mounting of the interchangeable inserts. The tool inserts are replaced without timedelay. No screws or temperature control hoses have to be disconnected. The change of the inserts lasts only seconds.

For most test specimens, the nozzle-side interchangeable insert is a mirror plate. The nozzle-side can also be supplied with pressure sensors or temperature sensors on request.

The mould nest for the test specimens is accommodated in the exchangeable insert on the closing side. The ejectors are connected directly to the ejector mechanism of the injection moulding machine. The test specimens can thus be produced free-falling for your material tests or removed by robots.